Manufacturing

SAP Business One revolutionizes manufacturing operations by harnessing cutting-edge cloud ERP technology to streamline processes and drive efficiency.

Enhancing Productivity

and Efficiency

SAP Business One equips you with advanced automation features and decision-support tools, including AI, predictive simulations, and real-time insights, to significantly boost productivity and operational efficiency.

Production engineering

Rapid design, setup, and adjustment of your production flow help create efficient and agile manufacturing operations.

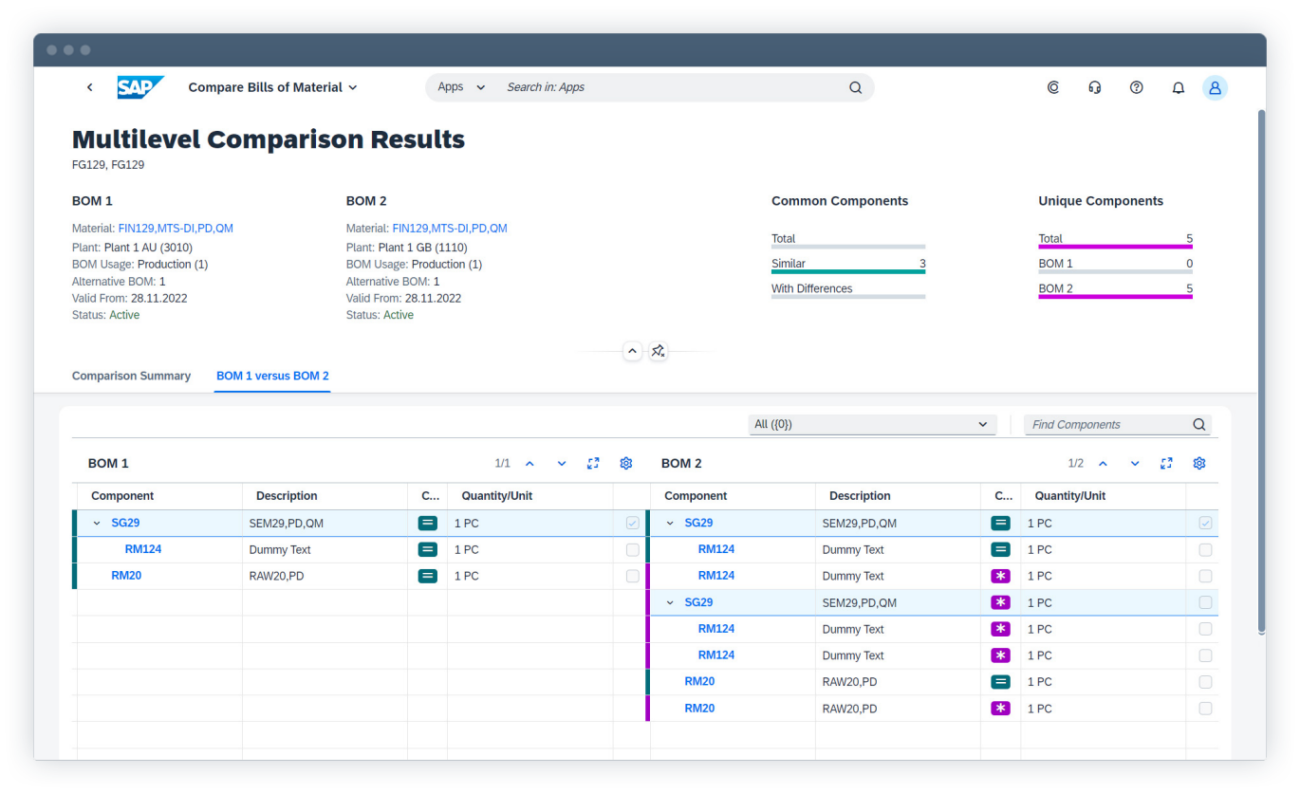

- Product and Production Setup Define critical elements like bills of materials (BOMs), routings, and work centers to ensure smooth and effective production operations.

- BOM Management Organize and evaluate bills of materials to streamline product updates and maintain structured manufacturing processes.

- Product Customization Streamline and integrate product configuration processes, accommodating the complexity that customers demand with ease.

Production planning

Intelligence based on real-time data and embedded AI paves the way to production optimisation.

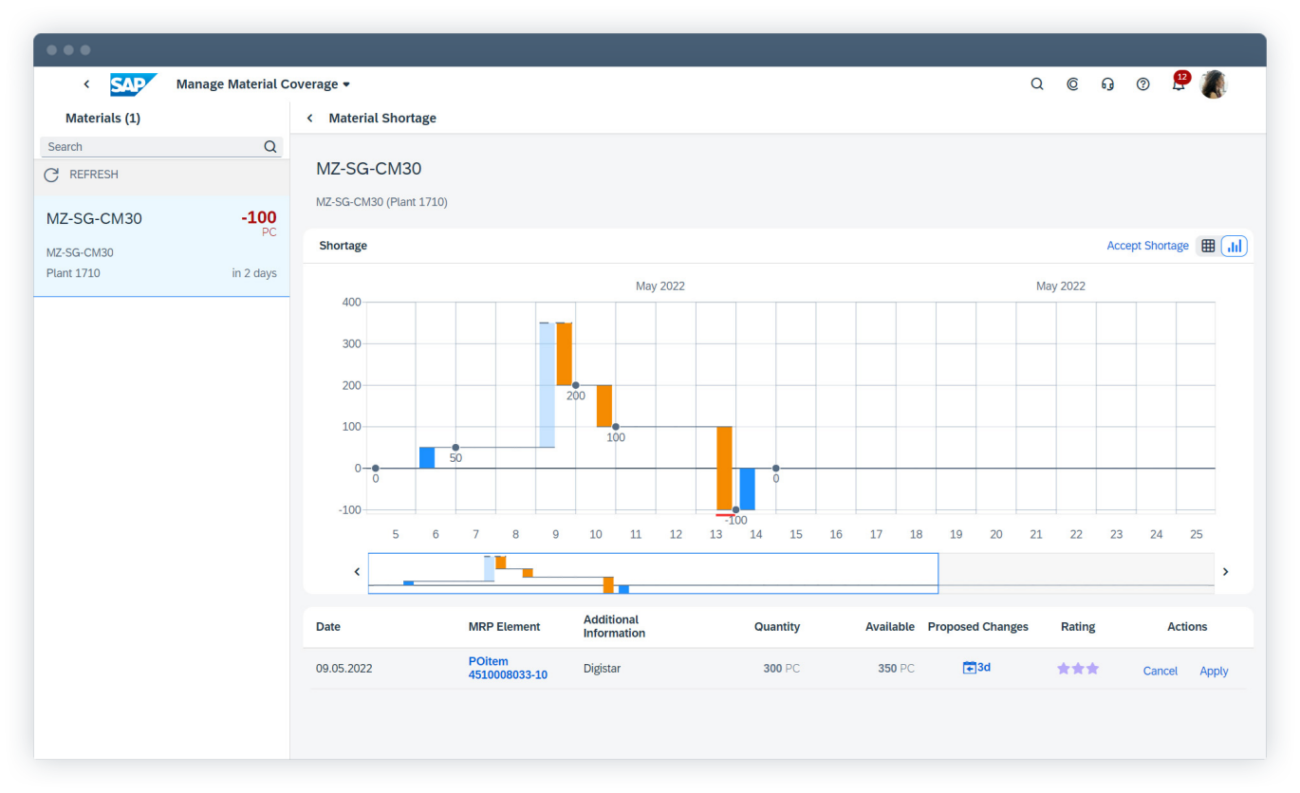

- Optimized Demand Forecasting Model and adjust demand forecasts while factoring in supplier and capacity constraints to achieve flexible and precise optimization.

- Harmonizing Supply and Demand Ensure materials are ordered automatically and arrive on time, aligning with production schedules to meet manufacturing goals.

- Efficient Capacity Management Track and manage work-center capacities to prioritize production orders effectively and maximize the utilization of resources and assets.

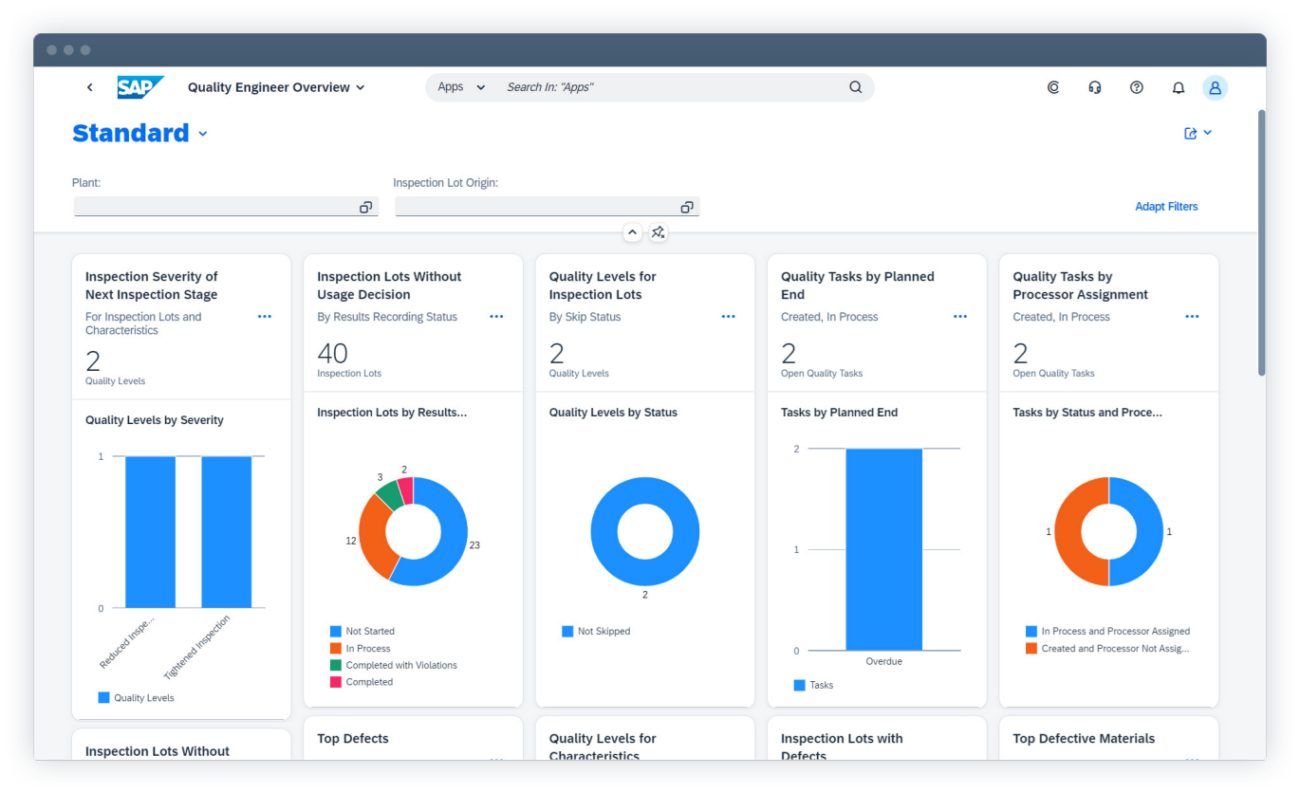

Quality management

Leveraging a cloud ERP with embedded quality management capabilities helps ensure your business delivers high-quality products.

- Development and implementation of quality measures Define holistically where and how to implement quality measures along the value-creation process.

- Inspections and capture of results Inspect materials against defined criteria and document them before using the data to decide on usage.

- Product and process improvement Analyse captured data to identify suitable follow-up actions, such as triggering an improvement process.

Manufacturing operations

Production control begins with comprehensive process transparency.

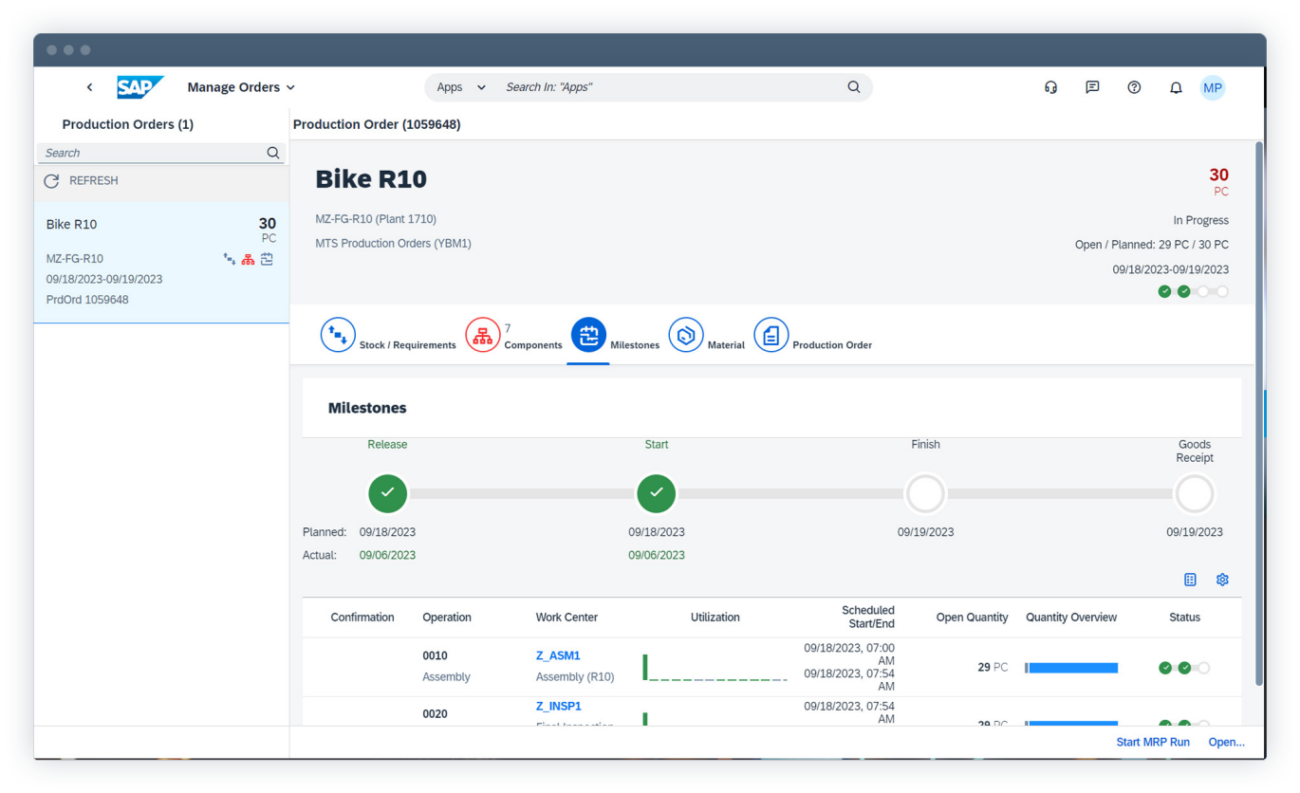

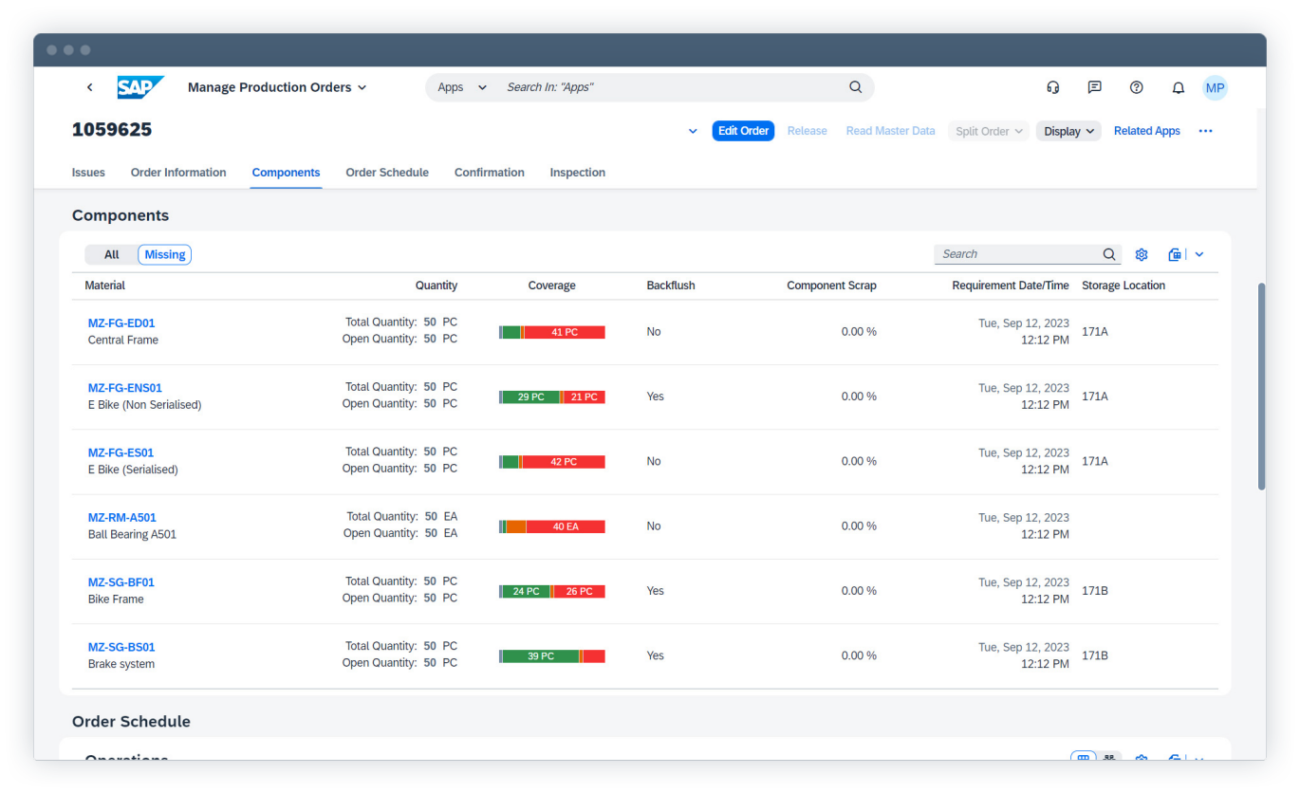

- Production Order Management Generate, modify, and oversee production orders before they are finalized and executed, ensuring smooth initiation of production activities.

- Live Production Tracking Gain control over production processes and expenses with real-time updates from the shop floor, allowing for immediate adjustments as needed.

- Proactive Production Oversight Utilize real-time data and alerts to identify and resolve potential issues early, preventing disruptions and maintaining efficient manufacturing operations.

Manufacturing options

Process automation can be supported across a broad range of manufacturing processes.

- Discrete Manufacturing Oversight Manage discrete manufacturing operations across various setups, including make-to-stock and engineer-to-order, ensuring efficient and adaptable production processes.

- Process Manufacturing Coordination Handle process manufacturing tasks using process orders and master recipes to streamline production and maintain consistency in output.

- Enhanced Process Management Implement supplementary processes such as repetitive manufacturing, Kanban, and just-in-time or just-in-supply replenishment to optimize production efficiency.

Transform Your Business with SAP Manufacturing

Rajlaxmi Solutions Pvt Ltd is your trusted partner in SAP Manufacturing, offering innovative solutions to streamline operations, enhance productivity, and reduce costs. Backed by years of expertise, we empower businesses to overcome challenges, achieve operational excellence, and maintain a competitive edge.

Features of SAP Manufacturing Solutions

Enhanced Productivity:

Automate manual tasks to minimize delays and maximize efficiency. Our SAP Manufacturing solutions ensure smooth collaboration across departments for increased productivity.

Real-Time Data Insights:

Get actionable insights with real-time analytics. Monitor every aspect of production and proactively address challenges.

Customizable Workflows:

Adapt our SAP Manufacturing solutions to meet your business’s unique needs. Flexible workflows ensure you’re ready for evolving demands.

Improved Quality Control:

Maintain top-notch product quality with built-in quality assurance tools. Detect and correct issues early, delivering consistent excellence.

Cost Optimization:

Cut down on waste, minimize downtimes, and allocate resources efficiently. Achieve higher returns with lower operational costs.

SAP Manufacturing in Production Engineering

SAP Manufacturing plays a pivotal role in production engineering by integrating advanced planning, execution, and monitoring tools. It enables engineers to design, optimize, and manage production workflows seamlessly.

Key benefits include:

- Process Optimization: Streamlined workflows reduce lead times and improve efficiency.

- Real-Time Monitoring: Get instant insights into production processes, enabling proactive decision-making.

- Enhanced Collaboration: Integration with design and planning tools ensures alignment across teams.

- Cost Efficiency: Minimize waste and optimize resource allocation.

Why Choose Rajlaxmi Solutions?

Rajlaxmi Solutions Pvt Ltd blends in-depth industry knowledge with SAP’s advanced tools to deliver scalable and effective manufacturing solutions. Whether it’s reducing inefficiencies or preparing for future demands, we have the expertise to transform your business operations.

Don’t let inefficiencies hold you back. Partner with Rajlaxmi Solutions Pvt Ltd and experience the unmatched power of SAP Manufacturing. Take the first step toward optimizing your operations today!

Tally Software

Tally Software

Customization

Customization

Tally Services

Tally Services

Tally Modules

Tally Modules

CRM

CRM

Contact and Lead Management

Contact and Lead Management

Sales Automation

Sales Automation

Pipeline Management

Pipeline Management

Reporting and Analytics

Reporting and Analytics

Contact center

Contact center

Marketing

Marketing

Tasks & Projects

Tasks & Projects

Tasks Assignment and tracking

Tasks Assignment and tracking

Project Planning and Management

Project Planning and Management

Gantt chart

Gantt chart

Time tracking

Time tracking

HR & Automation

HR & Automation

Employee Engagement Tools

Employee Engagement Tools

Workflow automation

Workflow automation

Worktime tracking & reports

Worktime tracking & reports

Absence management

Absence management

Announcements & appreciations

Announcements & appreciations

Requests & approvals

Requests & approvals

Collaboration

Collaboration

Project Colabration Tool

Project Colabration Tool

Document Sharing and Management

Document Sharing and Management

Online documents

Online documents

Drive

Drive

Webmail

Webmail

Copilot

Copilot

CoPilot in CRM

CoPilot in CRM

CoPilot in Tasks

CoPilot in Tasks

CoPilot in Chat

CoPilot in Chat

Mobile & SEO friendly

Mobile & SEO friendly

CoPilot in Feed

CoPilot in Feed

CoPilot in Sites & Stores

CoPilot in Sites & Stores

Financial management

Financial management

Accounting

Accounting

Controlling

Controlling

Fixed asset management

Fixed asset management

Banking and reconciliation

Banking and reconciliation

Financial reporting and analysis

Financial reporting and analysis

Manufacturing

Manufacturing

Production engineering

Production engineering

Production planning

Production planning

Quality management

Quality management

Manufacturing options

Manufacturing options

Manufacturing operations

Manufacturing operations

Sales and customer management

Sales and customer management

Customer order management

Customer order management

Billing and invoicing

Billing and invoicing

Customer returns

Customer returns

Price management

Price management

Sales rebate management

Sales rebate management

Supply chain

Supply chain

Inventory management

Inventory management

Order promising

Order promising

Asset management

Asset management

Technical asset management

Technical asset management

Demand monitoring

Demand monitoring

Maintenance execution

Maintenance execution

Planning, scheduling and dispatching

Planning, scheduling and dispatching

Reporting

Reporting

Accounting

Accounting

Accounting Masters

Accounting Masters

Payments

Payments

Tax Masters

Tax Masters

Share Management

Share Management

Banking

Banking

Manufacturing

Manufacturing

Production

Production

Bill of Materials

Bill of Materials

Reports

Reports

Tools

Tools

Assets

Assets

Maintenance

Maintenance

Asset Movement

Asset Movement

Asset Activity

Asset Activity

Asset Maintenance

Asset Maintenance

CRM

CRM

Sales Pipeline

Sales Pipeline

Masters

Masters

Reports

Reports

Campaign

Campaign

Website

Website

Blog

Blog

Web Site

Web Site

Support

Support

Issues

Issues

Maintenance

Maintenance

Warranty

Warranty